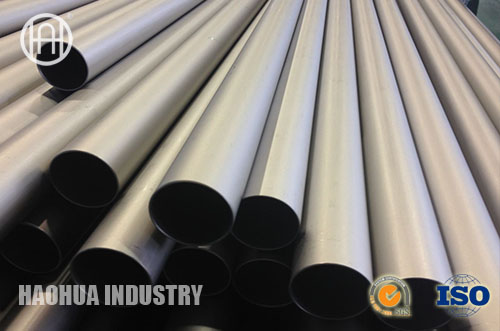

Titanium Tube

Product Categary:

Main Feature:

TitaniumTube The density of titanium is about 60 percent of that of steel- or nickel-ba

product description

Titanium Tube

The density of titanium is about 60 percent of that of steel- or nickel-based alloys giving significant weight savings in aerospace structures. The tensile strength is better than that of austenitic or ferritic stainless steels. Titanium is exceptionally corrosion resistant and exceeds the resistance of stainless steels in most environments. The metal is non-magnetic too, and has good heat transfer properties, with a melting point higher than steel alloys.Titanium is easily worked. Combine that with its strength, stiffness, toughness and high melting point and it’s a very desirable metal for high performance metal tubing. We manufacture titanium tubes used in aircraft hydraulic systems, medical implants, offshore drilling rig components, subsea equipment, and marine and chemical processing plants.

Type of product Grade(s) Technical requirements

according to

Titanium tubes and pipes Ti and Ti alloy grades 1, 2, 3, 7, 9, 11, 12, 16, 17, 26 and 28 ASTM B337, ASTM B338, ASME SB338

NACE MRO 175-94, Dimensional tolerances acc. to DIN 17861 D3/T3 or closer

HAOHUA INDUSTRY makes it easy to find the ASTM B338 welded or seamless titanium tubing you need to complete your project. Seamless tubes are available from 1/8″ through 6″ and titanium welded tube dimensions are between 1″ and 24″.

Because of its strength, unique density and corrosion resistance, titanium has found applications in many industries. For high quality tubing products, it’s often a better substance to use than competing materials like stainless steels or super alloys.