ASTM A312 TP410S stainless steel U bend tube

Product Categary:

Main Feature:

Jiangsu Haohua Industry Group as one of the leading suppliers in China to supply ASTM A312 TP410S stainless steel U bend tube etc. [Contact person:Ms chris ; Email: chris@haopipe.com ; Mob: 0086-180-515-86050]

product description

ASTM A312 TP410S stainless steel U bend tube

'U' Bend Stainless Steel Tubes are manufactured in our plant as per the customer requirements. Bends can be Heat Treated in accordance with Clients' requirements followed by hydrostatic testing and dye penetrant testing if required.

U bent tubes are widely used in heat-exchanger systems. Heat exchanger equipment on the basis of stainless U-tube is essential in strategically important and critical fields nuclear and petrochemical machine building.

U-tube heat exchangers Designed for high temperature applications, especially steam condensing or hot oil systems. Thïs model is selected when differential expansion makes a fixed tube sheet exchanger unsuitable and when conditions preclude a floating head type (HPF) selection.

Surface condition Finished U-tubes shall be free of scale, without scratches after bending

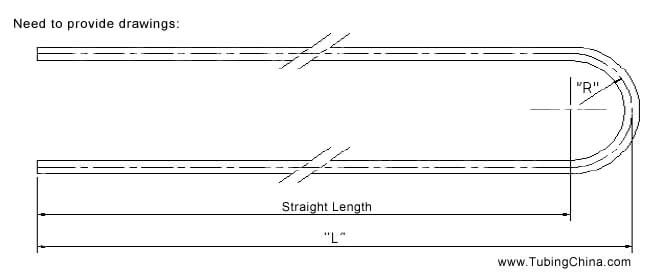

Dimensional tolerances U tubes acc. to TEMA R.C.B.

Dimensional tolerances U tubes acc. to TEMA R.C.B.

1) Length of straight part -0/+5 mm

Flattening (also called “ovality”) at the bend shall not exceed 10% of the nominal tube outside diameter.

Wall thickness in bending part acc. to TEMA R.C.B 2.31

2) Minimum tube wall thickness in the bend part (T min)T(min) ≥ (SW × (2×R + D))/( 2× (R+D)

where: SW is smallest wall thickness

D Nominal outside diameter

R radius

3)Radius tolerance

1) for R 100 mm +/- 3 mm

2) for R ≥ 100 mm +/- 5 mm

4). Straightness tolerance max. 1,5 mm per 1 m

U-Tube ends: plain, vertically cut to the tube axis

Tubes OD in mm can be bent upon agreement: 15.8 16.0 17.0 18.0 19.05 20.0 21.3 25.4 26.7 31.8 32.0 38.1mm

Initial Length

Maximum lengths of 27000mm can be supplied on request

Bending radius

Minimum: 1.5×OD

Maximum: 1500 mm

The dimensions for heat exchanger tubes in special grades may differ from the above,please contact us.

Our Tube-bending production line, installed at 2007, will allow to produce U-tubes as per standards:

1. ASTM A688/A688M-15 Specification for Seamless and Welded Austenitic Stainless Steel Feedwater Heater Tubes

2. ASTM A803/A803M-12 Standard Specification for Seamless and Welded Ferritic Stainless Steel Feedwater Heater Tubes

3. ASTM A556/A556M-12 Standard Specification for Seamless Cold-Drawn Carbon Steel Feedwater Heater Tubes

Main Testing Terms and Procedure:

- 1. Heat Treatment and Solution Annealing / Bright Annealing

- 2. Cutting to required length and deburring;

- 3. Chemical Composition Analysis Test With 100% PMI and One tube from each heat by Direct Reading Spectrometer

- 4. Visual Test and Endoscope Test for Surface Quality Test

- 5. 100% Hydrostatic Test and 100% Eddy Current Test

- 6. Ultrasonic Test subject to the MPS (Material Purchase Specification)

- 7. Mechanical Tests includes Tension Test, Flattening Test, Flaring Test, Hardness Test

- 8. Impact Test subject to Standard request

- 9. Grain Size Test and Intergranular Corrosion Test

- 10. Ultrasoic measuring of Wall Thickness

- 11. Stress Relieve Annealing on U bend Parts after bending